What Is the Wood-Carving Process?

Hand Carving

Wood sets an aesthetic tone. Whether in the home, the office, or the retail space, woodwork gets noticed. Carved woodwork enhances the aesthetic, emphasizing a focal area or setting a decorative palette. The art of carving wood has been with us for centuries. Traditionally, wood carving has been performed by hand through techniques passed down from skilled artisans to apprentices and more recently through books and guides and today via social media and workshops. In this overview we’ll review the wood-carving process and its challenges, as well as today’s wood-carving innovations using computer-driven machinery.

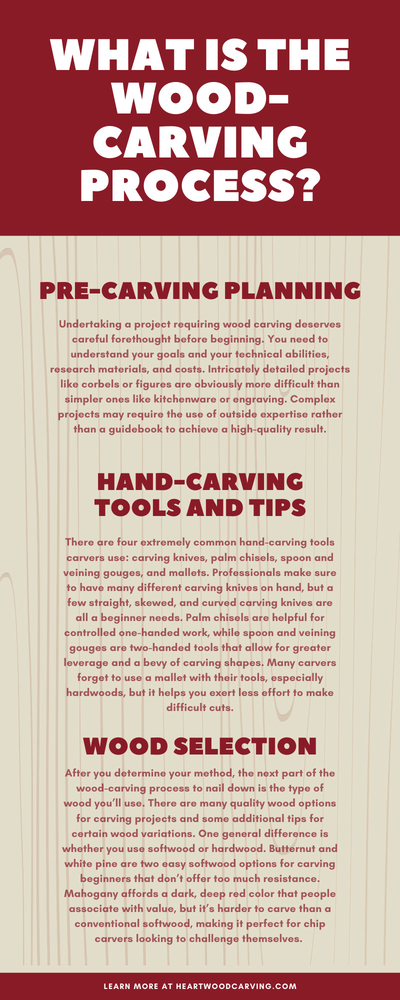

Pre-Carving Planning

Undertaking a project requiring wood carving deserves careful forethought before beginning. You need to understand your goals and your technical abilities, research materials, and costs. Intricately detailed projects like corbels or figures are obviously more difficult than simpler ones like kitchenware or engraving. Complex projects may require the use of outside expertise rather than a guidebook to achieve a high-quality result.

Hand Carving or Machine Carving

There are two major methods for wood carving in use today: hand carving and machine carving.

Hand Carving

As mentioned previously, hand carving has been with us since ancient times in both stone and wood. Carving in wood is typically exemplified in terms of technique. The two more popular methods either create a relief (revealing art within the piece) or engraving, where the pattern of lines created the art. In relief, the craftsman incorporates a knife (or chisel, gouge, or chainsaw) and removes material to reveal a work (i.e., bas relief, where the art is raised slightly from the background), whereas chip carving uses the tool created indentures determined by the tool choice to create the pattern that then becomes the artwork. In this case, the surface works in harmony with the pattern. Intricate projects require a solid understanding of fine art techniques and a variety of specialty tools that can take years to master, but simpler projects are often about perseverance and practice and require only a few tools. Think about your first whittling experience and recall when a small knife and a simple piece of wood were enough to get you started.

Hand-Carving Tools and Tips

There are four extremely common hand-carving tools carvers use: carving knives, palm chisels, spoon and veining gouges, and mallets. Professionals make sure to have many different carving knives on hand, but a few straight, skewed, and curved carving knives are all a beginner needs. Palm chisels are helpful for controlled one-handed work, while spoon and veining gouges are two-handed tools that allow for greater leverage and a bevy of carving shapes. Many carvers forget to use a mallet with their tools, especially hardwoods, but it helps you exert less effort to make difficult cuts. It’s best to always practice your cuts on a separate piece of wood to ensure you put these tools to good use. Also, you should take care to strop, or sharpen, your tools often to make your carving easier. One final tip—buy tools made with carbon steel so you can choose harder woods and make smoother cuts.

CNC Machine Carving

CNC Carving

Today’s advances in software and CNC machining allow for highly intricate wood carving. For example, Heartwood Carving utilizes machine carving to create detailed, predesigned

architectural wood carvings or to construct custom items. CNC machine carving is an excellent choice should you need several identical items made or a reproduction piece that is beyond your personal abilities.

To make a CNC carved object (or 3D printed object) first requires a 3D model of the art. This needs to be created in software from a design artist or can be created via a scan of an existing object. Once created, the art can then be sent to a CNC machine for carving. The process takes advantage of highly skilled technicians and equipment and is therefore costly but otherwise precise and fairly fast compared to hand-working several pieces. Yes, some woodworkers actually purchase tabletop CNC machines that are in the $2,000 to $5,000 range as one tool in their shop and then download programs from websites that offer 3D art files. Again, consider your computer and machining abilities as well as your budget when exploring this option, as it will require a new form of learning curve outside of regular woodwork to be able to make the software and CNC work together.

Once the art file is concluded, the designer needs the CNC router to coordinate with the computer model to execute the design designs. The post processor or “toolpathing” file. This is the code (G code) that the CNC (computer numeric control) machine uses to make its movements. The carving is performed via a motor attached to a bridge moving in the long direction (X direction) while the motor can move left and right along the bridge (Y direction) and up and down (Z direction). This combination of movement is what permits relief machining in a three-axis configuration. This spindle motor rotates a router bit at a high rate to perform the carving cuts in a raster or vector-type path. A raster path is a sequential machining of lines to reveal an image much like an ink-jet printer making a photo, whereas a vector path travels along a prescribed line and depth to create an engraving. Raster toolpaths can take a long time to conclude and are the standard choice for relief caring, whereas vectors are very fast and useful for letters and numbers.

Wood Selection

After you determine your method, the next part of the wood-carving process to nail down is the type of wood you’ll use. There are many

quality wood options for carving projects and some additional tips for certain wood variations. One general difference is whether you use softwood or hardwood. Butternut and white pine are two easy softwood options for carving beginners that don’t offer too much resistance. Mahogany affords a dark, deep red color that people associate with value, but it’s harder to carve than a conventional softwood, making it perfect for chip carvers looking to challenge themselves.

Meanwhile, harder woods are suitable for CNC machine techniques. Denser, tight-grained woods such as cherry or maple are consistent and rigid enough to allow a machine cut to be even and hold up to the rigors of the process. Additional sanding and cleaning of machine-carved parts is required to remove fuzz and tool marks.